焦耳热资讯

利用闪蒸焦耳热处理废塑料零净成本合成清洁氢气

点击:0 时间:2023-06-17 08:43:46

原文: 1686963336d91e07.pdf

1686963336d91e07.pdf

链接:https://onlinelibrary.wiley.com/doi/epdf/10.1002/adma.202306763

氢气(H2)是无污染能源生产的主要可储存燃料,全球每年使用量超过9000万吨。95%以上的H2是通过金属催化的蒸汽甲烷重整合成的,每吨H2产生11吨CO2。使用可再生能源电解水产生的“绿色H2”产生亚化学计量的二氧化碳,但成本高出2-3倍,目前在经济上不可行。在这里,我们报道了废塑料与高纯度石墨烯一起无催化剂转化为清洁的“闪蒸H2”。可扩展的程序在解构聚烯烃时不会产生CO2,并以高质量产率产生纯度高达94%的H2。石墨烯副产品的销售仅为其当前价值的5%,产生了负成本的H2生产。生命周期评估表明,与其他H2生产方法相比,排放量减少了39-84%,这表明闪蒸H2工艺是一种经济可行的清洁H2生产路线。

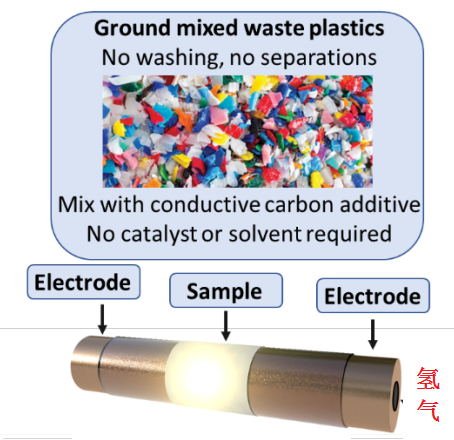

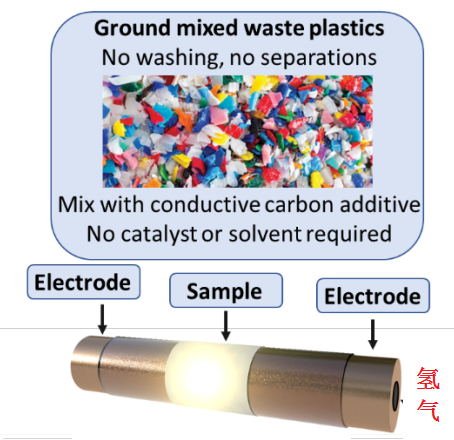

Hydrogen gas (H2) is the primary storable fuel for pollution-free energy production, with over 90 million tonnes used globally per year. More than 95% of H2 is synthesized through metal-catalyzed steam methane reforming that produces 11 tonnes of CO2 per tonne H2. “Green H2” from water electrolysis using renewable energy produces sub-stoichiometric CO2, but costs 2-3x more, making it presently economically unviable. Here we report catalyst-free conversion of waste plastic into clean “flash H2” along with high purity graphene. The scalable procedure evolves no CO2 when deconstructing polyolefins and produces H2 in purities up to 94% at high mass yields. Sale of the graphene byproduct at just 5% of its current value yields H2 production at negative cost. Life-cycle assessment demonstrates a 39-84% reduction in emissions compared to other H2 production methods, suggesting the flash H2 process to be an economically viable, clean H2 production route.

链接:https://onlinelibrary.wiley.com/doi/epdf/10.1002/adma.202306763

氢气(H2)是无污染能源生产的主要可储存燃料,全球每年使用量超过9000万吨。95%以上的H2是通过金属催化的蒸汽甲烷重整合成的,每吨H2产生11吨CO2。使用可再生能源电解水产生的“绿色H2”产生亚化学计量的二氧化碳,但成本高出2-3倍,目前在经济上不可行。在这里,我们报道了废塑料与高纯度石墨烯一起无催化剂转化为清洁的“闪蒸H2”。可扩展的程序在解构聚烯烃时不会产生CO2,并以高质量产率产生纯度高达94%的H2。石墨烯副产品的销售仅为其当前价值的5%,产生了负成本的H2生产。生命周期评估表明,与其他H2生产方法相比,排放量减少了39-84%,这表明闪蒸H2工艺是一种经济可行的清洁H2生产路线。

Hydrogen gas (H2) is the primary storable fuel for pollution-free energy production, with over 90 million tonnes used globally per year. More than 95% of H2 is synthesized through metal-catalyzed steam methane reforming that produces 11 tonnes of CO2 per tonne H2. “Green H2” from water electrolysis using renewable energy produces sub-stoichiometric CO2, but costs 2-3x more, making it presently economically unviable. Here we report catalyst-free conversion of waste plastic into clean “flash H2” along with high purity graphene. The scalable procedure evolves no CO2 when deconstructing polyolefins and produces H2 in purities up to 94% at high mass yields. Sale of the graphene byproduct at just 5% of its current value yields H2 production at negative cost. Life-cycle assessment demonstrates a 39-84% reduction in emissions compared to other H2 production methods, suggesting the flash H2 process to be an economically viable, clean H2 production route.

相关新闻

- 过氧化氢电合成突破:配位调控+8秒焦耳加热,碘氮催化剂选择性近96%且高产 [2025-07-22]

- 锂电负极材料新进展:3 秒焦耳加热制高熵氧化物,循环性能超同类材料 [2025-07-22]

- 双相高熵合金工艺新进展:30 秒闪速焦耳退火优化TRIP型高熵合金的力学性能 [2025-07-22]

- 海水淡化技术新突破:双喷嘴3D打印,-25℃冷冻,12h高盐无结晶 [2025-07-22]

- 电池再利用新成果:焦耳热合成高熵催化剂,锂-氧电池循环寿命破240次 [2025-06-28]

- 碳基材料新突破:焦耳热(1000–2000°C)梯度调控实现吸收-导热协同优化 [2025-06-28]