焦耳热资讯

通过闪蒸焦耳加热回收锂离子电池金属

点击:0 时间:2023-06-17 08:37:30

原文: 16869625419ce01d.pdf

16869625419ce01d.pdf

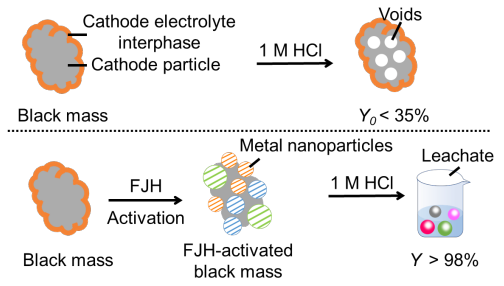

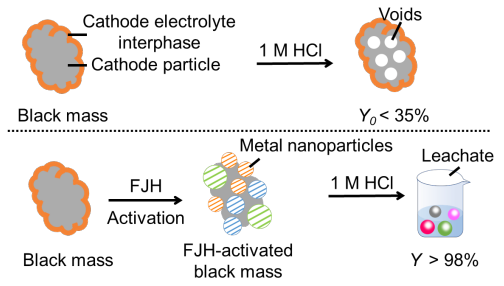

报废锂离子电池(LIBs)的惊人积累和电池金属来源的日益稀缺,引发了对有效回收策略的迫切呼吁。然而,以高效率和低环境足迹回收这些金属是具有挑战性的。我们在这里使用脉冲直流闪蒸焦耳加热(FJH)策略,在几秒钟内将黑色物质(阳极和阴极的组合)加热到>2100 K,导致后续浸出动力学增加约1000倍。所有电池金属的回收率都很高,无论其化学性质如何,甚至使用0.01M HCl等稀释酸,从而减少了二次废物流。超快高温实现了钝化的固体电解质界面的热分解和难以溶解的金属化合物的价态还原,同时减轻了挥发性金属的扩散损失。生命周期分析与当前的回收方法表明,FJH显著减少了废LIB加工的环境足迹,同时将其转变为一种具有经济吸引力的工艺。

The staggering accumulation of end-of-life lithium-ion batteries (LIBs) and the growing scarcity of battery metal sources have triggered an urgent call for an effective recycling strategy. However, it is challenging to reclaim these metals with both high efficiency and low environmental footprint. We use here a pulsed direct current flash Joule heating (FJH) strategy that heats the black mass, the combined anode and cathode, to >2100 K within seconds, leading to ~1000-fold increase in subsequent leaching kinetics. There are high recovery yields of all the battery metals, regardless of their chemistries, using even diluted acids like 0.01 M HCl, thereby lessening the secondary waste stream. The ultrafast high-temperature achieves thermal decomposition of the passivated solid-electrolyte-interphase and valance-state reduction of the hard-to-dissolve metal compounds, while mitigating diffusional loss of volatile metals. Life-cycle-analysis vs current recycling methods shows that FJH significantly reduces the environmental footprint of spent LIB processing, while turning it into an economically attractive process.

报废锂离子电池(LIBs)的惊人积累和电池金属来源的日益稀缺,引发了对有效回收策略的迫切呼吁。然而,以高效率和低环境足迹回收这些金属是具有挑战性的。我们在这里使用脉冲直流闪蒸焦耳加热(FJH)策略,在几秒钟内将黑色物质(阳极和阴极的组合)加热到>2100 K,导致后续浸出动力学增加约1000倍。所有电池金属的回收率都很高,无论其化学性质如何,甚至使用0.01M HCl等稀释酸,从而减少了二次废物流。超快高温实现了钝化的固体电解质界面的热分解和难以溶解的金属化合物的价态还原,同时减轻了挥发性金属的扩散损失。生命周期分析与当前的回收方法表明,FJH显著减少了废LIB加工的环境足迹,同时将其转变为一种具有经济吸引力的工艺。

The staggering accumulation of end-of-life lithium-ion batteries (LIBs) and the growing scarcity of battery metal sources have triggered an urgent call for an effective recycling strategy. However, it is challenging to reclaim these metals with both high efficiency and low environmental footprint. We use here a pulsed direct current flash Joule heating (FJH) strategy that heats the black mass, the combined anode and cathode, to >2100 K within seconds, leading to ~1000-fold increase in subsequent leaching kinetics. There are high recovery yields of all the battery metals, regardless of their chemistries, using even diluted acids like 0.01 M HCl, thereby lessening the secondary waste stream. The ultrafast high-temperature achieves thermal decomposition of the passivated solid-electrolyte-interphase and valance-state reduction of the hard-to-dissolve metal compounds, while mitigating diffusional loss of volatile metals. Life-cycle-analysis vs current recycling methods shows that FJH significantly reduces the environmental footprint of spent LIB processing, while turning it into an economically attractive process.

相关新闻

- 过氧化氢电合成突破:配位调控+8秒焦耳加热,碘氮催化剂选择性近96%且高产 [2025-07-22]

- 锂电负极材料新进展:3 秒焦耳加热制高熵氧化物,循环性能超同类材料 [2025-07-22]

- 双相高熵合金工艺新进展:30 秒闪速焦耳退火优化TRIP型高熵合金的力学性能 [2025-07-22]

- 海水淡化技术新突破:双喷嘴3D打印,-25℃冷冻,12h高盐无结晶 [2025-07-22]

- 电池再利用新成果:焦耳热合成高熵催化剂,锂-氧电池循环寿命破240次 [2025-06-28]

- 碳基材料新突破:焦耳热(1000–2000°C)梯度调控实现吸收-导热协同优化 [2025-06-28]